You’ve probably heard a lot about lithium-ion batteries—they power everything from our phones to our cars. But there’s a new kid on the block that scientists are really excited about: the aluminum-ion battery. 🧪

Why the excitement? Aluminum is cheap, super abundant (it’s the most common metal in the Earth’s crust!), and can theoretically store a ton of energy. Plus, it’s much safer and less likely to catch fire than lithium. Sounds perfect, right? Well, moving from a cool idea in the lab to a battery in your hands is a tricky business. Here are the biggest roadblocks holding back mass production.

Challenge #1: Finding the Perfect Partner (The Cathode Problem)

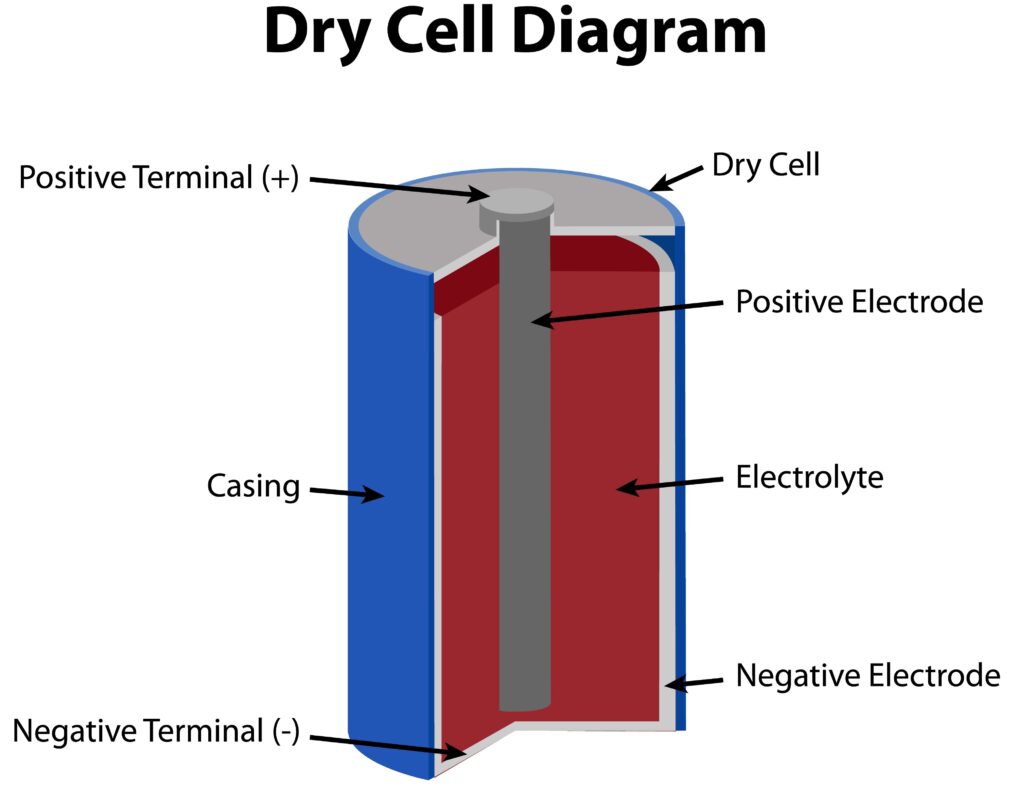

Think of a battery like a dance floor. Tiny charged particles (ions) have to move from one side (the anode) to the other (the cathode) to create electricity. For aluminum batteries, the aluminum anode is ready to go. The problem is finding the perfect cathode partner.

Aluminum ions are big and carry a lot of charge (Al3+). When they move into the cathode material, they’re like a clumsy dancer who bumps into everything. This strong interaction can damage the cathode’s structure over time, causing the battery to lose its ability to hold a charge. Scientists are hunting for a material that’s both welcoming and tough enough to handle aluminum’s energetic moves, again and again.

Challenge #2: The “Battery Juice” is Too Spicy (The Electrolyte Problem)

The liquid that lets the ions flow between the anode and cathode is called the electrolyte. For aluminum batteries, the most effective electrolyte researchers have found so far is a type of ionic liquid. The catch? This stuff is highly corrosive. corrosive. It’s like filling your car’s engine with acid—it might work, but it will eat away at the other parts over time.

This “spicy” electrolyte is also very sensitive to moisture. Even a tiny bit of water can mess up the whole reaction. This means factories would need to be incredibly dry and controlled, which makes manufacturing complicated and expensive. 💸

Challenge #3: A Stubborn Self-Defense Layer (The Anode Problem)

You know how aluminum foil doesn’t really rust? That’s because aluminum instantly reacts with air to form a super-thin, tough, and insulating layer of aluminum oxide. While this is great for protecting your leftovers, it’s a nightmare for a battery.

This oxide layer acts like a wall, making it difficult for the aluminum ions to leave the anode in the first place. Scientists have to find clever ways to get around this barrier without compromising the battery’s safety and performance.

Challenge #4: The Performance Gap

Let’s be real: lithium-ion batteries have had a 30-year head start. They are incredibly good at what they do. Right now, most aluminum-ion prototypes just can’t compete in a few key areas:

- Energy Density: They can’t pack as much power into the same amount of space as lithium-ion batteries. This is a big deal for things like smartphones and electric cars, where size and weight matter.

- Voltage: The voltage they produce is often lower, which means you get less “oomph” out of them.

While researchers have made some amazing progress, closing this performance gap is essential for aluminum batteries to become a true competitor.

So, What’s Next?

Don’t get me wrong, the future for aluminum batteries is still incredibly bright! ☀️ These challenges are not impossible roadblocks; they are complex puzzles that brilliant scientists around the world are working hard to solve.

Every day, new materials and chemistries are being tested. The goal is to create an aluminum battery that is not only cheap and safe but also powerful and long-lasting. Once we crack that code, it could completely change the game for energy storage. So, keep an eye out—the battery revolution might just be made of aluminum!